This is the story of the round, midrange horns pictured and their (part) DIY construction in Fibreglass.

“It remains hard to convince people, including acoustical engineers, that the midrange is where we live, and it is in the midrange that distortion is the most annoying and where amplitude response errors are most prominently evident. i have spent more man-hours of R & D time on the midrange than on the bass.”

Paul Klipsch, 1971

Horns are ‘acoustic transformers’… they give the driver a good load to drive and allow the high sound pressure produced by the driver diaphragm to be gradually and smoothly ‘transformed’ down to room air pressure level. The power and efficiency of the driver is increased.

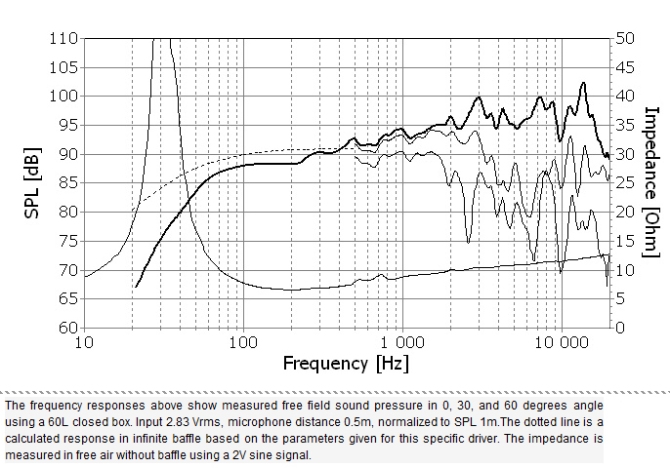

This midrange horn was originally made for Lowther drivers, but has been used also with Field Coil drivers & currently in use with SEAS FA22RCZ drivers.

I was attracted to the sound of ‘full-range drivers’ (‘wide-range’ would be a better description):

- I like the transparent sound of minimal-crossover in the important midrange.

- I like the ‘speed’ of lightweight paper cones driven by a strong magnet.

- The high sensitivity of these drivers (94-96dB/W typically) allows the use of low power, elegantly simple, short signal path, amplification (eg. triodes).

However, these drivers typically have rising frequency response, with stronger output in the upper midrange-low treble. (‘Whizzer’ cones also have problems – but that’s another story!)

Midrange horn-loading boosts the lower midrange frequencies (depending on horn size), gives an enhanced sense of scale and effortless, open, macro and micro dynamics. The driver does not struggle to ‘throw’ a sound wave into the room.

Lowther PM4 in 140Hz mid horn – rough 1/3 octave response plots at listening seat, showing off-axis response with reduction of upper midrange peak.

My chosen design cut-off frequency (Fc) was 140Hz – LF roll-off often starts at 1/3 to 1/2 octave higher, eg. around 200hz.

The choice of the Tractrix horn flare profile was influenced by many things, including:

- J Dinsdale, “Horn Loudspeaker Design” in Wireless World 1974, concluded, “…both theoretical considerations and very careful listening tests by the author and others tend to support the claims that the tractrix is the optimum horn contour.“

- Dinsdale claimed that the Tractrix contour “…combined the excellent low frequency characteristics of the exponential curve with the spherical wave propagation characteristics of a conical horn“. (Bruce Edgar, “The Tractrix Horn Contour”, Speaker Builder, 2/81)

- The Tractrix profile “launches spherical waves that can yield excellent stereo imaging effects” (Bruce Edgar, “The Edgar Midrange Horn”, Speaker Builder, 1/86)

- “The tractrix’s reduced length compared with conical or exponential horns of the same frequency range gives the advantage of being smaller than other horn contours.” ( Bruce Edgar, “The Tractrix Horn Contour”, Speaker Builder, 2/81)

- The Tractrix curve is generated from the mouth (not from the throat like most other horn profiles, except Le Cleac’h) and so, mouth-room termination is more gentle, more ideal & more efficient, in air-pressure terms. The Tractrix horn mouth terminates when curve tangent is 90° to the horn axis. “Keele found that beaming effects of conical and exponential horns can be minimized by doubling the flare at the mouth.” ( Bruce Edgar, “The Tractrix Horn Contour”, Speaker Builder, 2/81)

Dr Bruce Edgar (Edgar Horn previously) has been responsible for much modern development in horn loudspeaker implementation, understanding and remedying colourations and addressing shortcomings that were typical of horn loudspeakers previously. (I was fortunate enough to spend most of a day with this learned and generous man, on a visit to LA in the mid ’90s.)

Dr Bruce Edgar’s drawing – from his “An Interview with P.G.A.H. Voigt – Pt 1”, Speaker Builder, 3/81.

Some history: The Tractrix horn contour was developed by the German-born, British audio-inventor P.G.A.H. (Paul) Voigt in 1926 (patented in 1927). We should pay some respect to Paul Voigt. Just a few of his innovations:

- He designed a loudspeaker driver in the mid-1920s, with ultra-light paper cone & ultra-high magnet strength coil (originally electromagnet field coil) – specifications still currently marketed by Lowther and others.

- Voigt invented the twin-cone loudspeaker, which was licensed to Wharfedale and Goodmans.

- Voigt patented the Tapered Quarter Wave Pipe (TQWP) enclosure concept for loading speakers.

- He developed horn loudspeakers for domestic and cinema use.

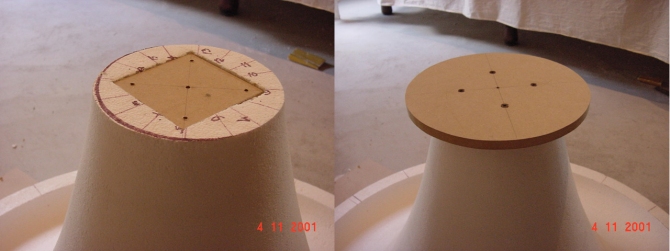

My Tractrix horn was to be cast in Fibreglass, so a mould needed to be made first. The easiest options were to use Polyurethane foam or Extruded (XPS) or Expanded (EPS) Polystyrene foam – Expanded Polystyrene (Styrofoam) was most economical.

I had no experience in Fibreglass, so I took advice from a Fibreglass workshop (Allied Fibreglass in Auckland). They hard-coated my Styrofoam mould, recoated and spray primer-coated it – for me to do all the simple, laborious hours of sanding and sanding and sanding….

The Styrofoam has been hard-coated by the Allied Fibreglass workshop, ready for more sanding, by me.

The final sandable spray coating has been applied, fine-sanded and minor imperfections filled with fine epoxy-filler before more fine-sanding.

Completed Fibreglass Tractrix horns – cast with white ‘gel-coat’ and increased layer thickness near mouth to reduce resonances:

Finally, a nice pic of….

Useful links:

- Tractrix Horn Calculator

- “Horn Loudspeaker Design” Pts 1 – 3, by J. Dinsdale, Wireless World 1974 – http://wp.volvotreter.de/dl-section/articles/

- “The Edgar Midrange Horn”, Bruce Edgar, Speaker Builder 1/86 – http://wp.volvotreter.de/dl-section/articles/

(Thank you, Volvotreter.)

Any comments welcome!

Update March 2016: Tractrix Midrange Horn – Drive Units

Pingback: Mauhorn IV | D a r k L a n t e r n

Pingback: Compound mid + basshorn (Part 1) | D a r k L a n t e r n

How does one contact “OBD” is SA for field coils? I looked, but no luck.

Looks like they would bolt onto my lowthers…

Cheers

Hi Max – thanks for dropping by – I checked with Mark if he is still making the OBDs, but unfortunately he is no longer in a position to produce any more, sorry. He has moved on to other areas of interest.

What is your Lowther setup?

Cheers, Owen

Pingback: Midhorn + Basshorn (Part 2) | D a r k L a n t e r n

Pingback: Basshorn (part 3 Construction) | D a r k L a n t e r n

Pingback: 2A3PP amplifier – upgrades | D a r k L a n t e r n

Very interested in your work . Can you please show some more picture with your seas fa22rcz?

Hi Vinh – i will post soon some details of the Seas FA22RCZ – mounting, fixing, etc. Is this what would be of interest? – Thanks for commenting. Cheers, Owen

Pingback: Tractrix midrange horn – drive units | D a r k L a n t e r n

Seas never lived in the same world as amazing lowther!

Haha, thanks for your opinion, Hans!

I have lived with PM2C, PM6A, PM4A – exciting but high maintenance & temperamental!

Cheers, Owen

Pingback: My music system | D a r k L a n t e r n

dear sir, I love horns but due to the expensive apartments in HongKong. I have to survive in a flat with a living room that is only 9ft wide. Currently I am using a JBL D2430K compression driver which delivers 800hz to 20K. This is great because all I want is a simple two way system. I am using an XTA as an audio management system and 2 Linn Klimax power amplifiers. However, I hate the Stereo Lab horns because I have to use an adaptor to convert it from a 2″ throat to a 1 1/2″ one. I ordered a 1 1/2″ one from Stereo Lab and they delivered one to me with holes that can only fit JBL 375. German engineering! I told them I am using a JB D2430K. I asked them what to do and no reply. It has beensix months, and I have to give up.

Can you make me a tractrix horn that can fit the JBL D2430K that delivers 800-20000hz? The horn can actually work its way to 40Khz. It has two coils in it but with one single slot very clever design.

Thank you for your attetntion,

Peter Ho

Hi Peter – thanks for your message & I hope that things are things are calm & peaceful for now in HK? I have a hi-fi pal in Tsing Yi.

Unfortunately, I have only one horn mould size & I can not make variation sizes.

I recommend contacting Martin Seddon (Azurahorn) in Australia. He has many horn sizes & throat variations – https://www.azurahorn.com

His Le Cléac’h profile horns are similar to my Tractrix horn.

Please mention my name.

Let me know how things go & I’d be pleased to see some pics of your horn system!

(You can contact me & send pics on our DarkLantern forum – http://darklantern.proboards.com )

Best Regards – Owen

what was the back chamber volume you ended up with using the seas fa22rcz because I’m doing almost the same exact set up as your horn and need to know where to start

Hi bill – the SEAS FA22RCZ is not ideal for horn-loading, T-S parameters are not ideal It works OK, but not ideal bass power. You can see that EBP (Efficiiency Bandwidth Product) is a little low for horn-loading.

My back-chamber volume is currently ~13Litres, but it would work better reduced to 6 – 8L.

In retrospect, my Throat size also is a little small – 81cm2 (I think ~115 would be better but I cannot change that easily now).

I will soon install (modified) Field Coil drivers again (similar T-S to Lowthers) & I will reduce back-chamber volume at same time.

Cheers – I will post an update on the FC drivers – Owen

my horns measure throat dia 17.5 cm x throat length 46 cm x mouth dia 81.28 cm

my horns measure throat dia 17.5 cm x throat length 46 cm x mouth dia 81.28 cm and are made out of thick mahogany maybe sarah brooks horn

Hi hornloaded – Nice, are your horns (i) front horns or rear horns (ii) floor, wall and/or corner loaded?

My finished front-rear horn design is here – https://darklanternforowen.wordpress.com/2015/11/09/basshorn-part-3-construction/

Cheer – Owen

I acquired these horns from the late Dr. bruce Edgar when he was closing up his shop because of health issue and gave me these horns . now back to my horns , yes front loaded much like yours , corner loaded – no my room won’t allow it . it would be centered on the long wall of the room at ear height sitting say 40″ off floor. i was wondering what the roll of of the lower end of the horn would be to crossover to the bass ? my choice for bass drivers i have on hand are JBL E145 15″, JBL 2245 18″ or TAD 1602 any ideas ?

Hi,darklanternowen!! I’m Do Kyung Lee and I’m an art college student in korea.

I’m designing a speaker for my graduation exhibition. While I search for references, I found your art works! they’re just amazing. And I was planning to make a horn-shaped speaker just like yours but I’m struggling to make the horn part.

If you don’t mind, can you tell me what was the process to make your speakers especially the horn-shaped one?

I fully understand that you can’t share all the details but if you can tell me some details, that would be really nice.

In korea, we can’t buy the plastic horn part, so we have to make it. if you have some tips on making that part, let me know.

Again, thanks for making those amazing pieces. It really inspires me! thanks for your time and hope to hear from you soon 🙂

Thanks! alswjd32121@naver.com here is my email. You can e-mail me!!

Hi Do Kyung Lee – thanks for visiting!

You can find a useful Tractrix Horn Calculator here – http://wp.volvotreter.de/dl-section/tools/

This should allow you to draw the Tractrix horn curve (flare), starting from the loudspeaker driver diameter (Sd).

Be sure to make a generous ‘roll’ at the large ‘mouth’ end.

Cheers – Owen